- An entry model of the YSM series that achieves the world's highest level * in its class while achieving both high speed and versatility.

- The ultimate basic machine featuring three "1" s

- Flexible support for production sites

- Function to realize stable production

*:Comparison of under the best conditions (CPH) of 1-beam, 1-head class surface mounters. (Our survey in January 2017)

Feature:

New scan camera:

The performance of the scan camera has been improved, and the size of compatible parts for high-speed mounting has been expanded to 12 mm. Supports ball recognition such as BGA and CSP.

Multi camera:

Recognizes parts with a size of over 12 mm or a height of over 6.5 mm at high speed and with high accuracy.

Nozzle station:

Automatic replacement of spare nozzles and custom nozzles is possible.

Basic Specifications:

| Target board dimensions | L510 x W460mm ~ L50 x W50mm * Available up to L950mm as an option |

| Mountable parts | 03015mm ~ W55 x L100mm (W45mm or more is divided recognition), height 15mm or less * Parts height 6.5mm or more, or part size 12mm or more requires a multi-camera (option) |

| Loading capacity | HM head (10 nozzles) specifications: 46,000 CPH (our optimum conditions) HM5 head (5 nozzles) specifications: 31,000 CPH (our optimum conditions) |

| Mounting accuracy Our optimum conditions (when using standard evaluation materials) |

± 0.035mm (± 0.025mm) Cpk >= 1.0 (3σ) |

| Number of parts types | Fixed plate: Up to 96 types (8 mm width tape feeder equivalent) Tray: 15 types (when equipped with sATS15, maximum, JEDEC) |

| Power supply specifications | Three-phase AC 200/208/220/240/380/400 / 416V ± 10% 50 / 60Hz |

| Supply air source | 0.45MPa or more, clean and dry |

| External dimensions | L1,254 x W1,440 x H1,445mm |

| Body mass | Approximately 1,270 kg |

Company Information:

HTGD (GDK) is committed to take the professional line, to enrich the SMT professional and technical service experience, process improvement and effective solutions, rich practical experience to provide customers with appropriate and economical and reliable recommendations to meet the special needs of all types of customers. The company established a head office in Shenzhen and set up branch offices in Dongguan, Suzhou, Tianjin, Chongqing, Xi'an and Xiamen. At the same time, there are many branches and agents overseas, forming a strong distribution and service network in the world.

Major application range is SMT & PCB assembly, consumer electronics products, auto industry, LED assembly, medical electronics industry, etc.

1.Shenzhen HTGD Intelligent Equipment Co., Ltd established in 2008.

2.300+ staffs

3.2,000 sets machines production capability per year

4.Sales and service covers 35+ countries around the world.

5.Focus on design&research based on customer’s request

6.HTGD & GDK two brands

7.40,000 square meter advanced standard production workshop

8.ISO 9001 approval and CE certificate

9.More than 80 utility model patents and 5 invention patents

10.30000+ big customers in China, who are specialized in cell phone, home appliance spare parts, medical electrical parts, etc.

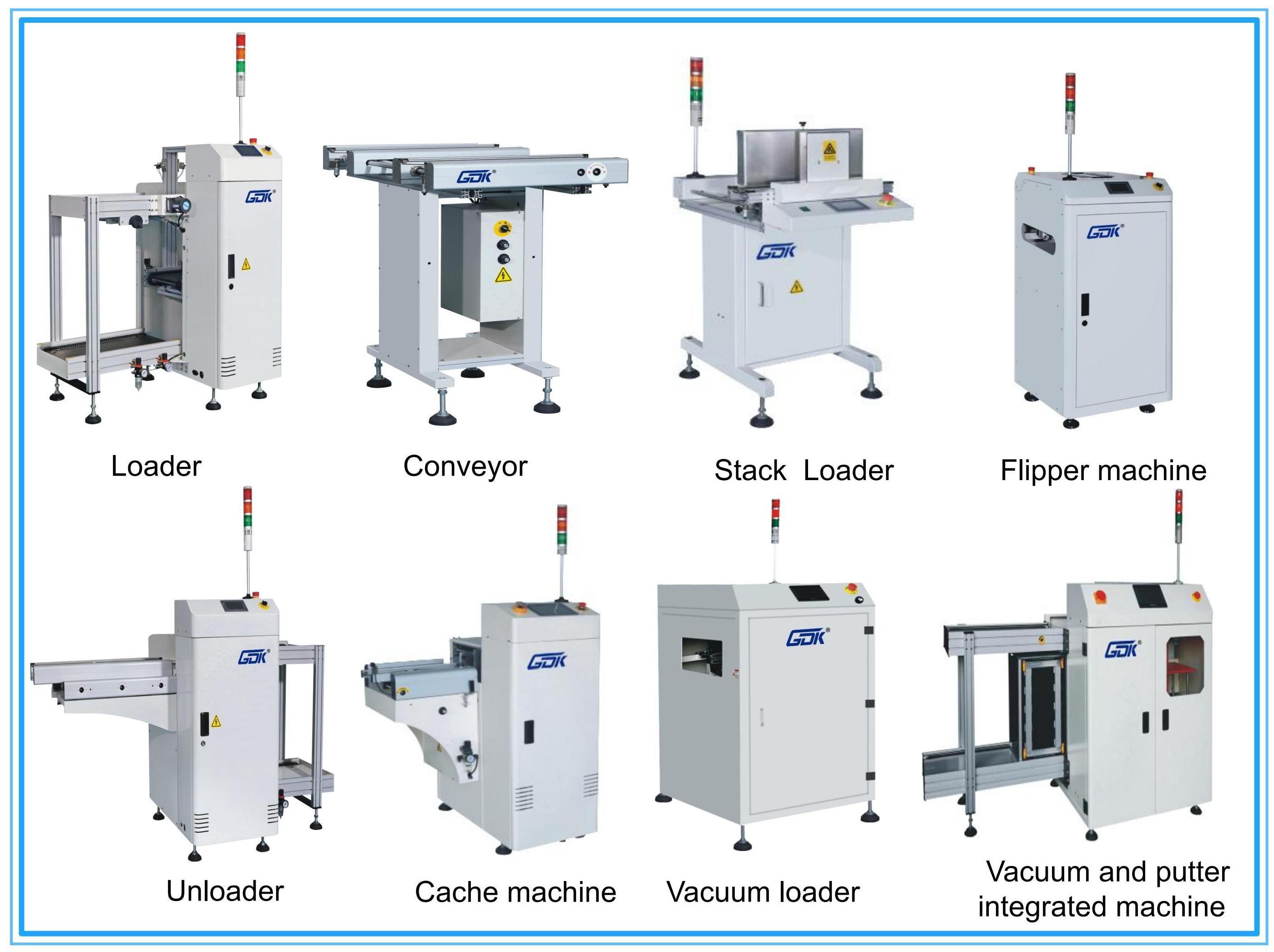

HTGD&GDK is focus on solder paste( screen printer), AOI, SPI, dispenser, loader, unloader, conveyor, reflow oven, design and produce, and provide SMT whole line service for customers around the world. Meanwhile provide THT whole line service too.

Production Line:

10000 square meters standard modern standard precision equipment production work.

After-Sales Service:

Technical support:

# From the purchase date, one year free warranty, lifelong maintenance

# Provide technical update and technical service at any time

# Software system life - long free upgrade, to ensure the latest version of the software and perfect functions

# Provide technical training according to customer needs

Service support:

# Since the date of purchase, the customer has become a lifetime member of our company and enjoys the all-day waiting service

# Make phone calls and on-site visits to customers from time to time, communicate with customers and improve related problems in a timely manner

# Provide door-to-door service, one - on - one designated service policy

Advantage, Why choose us:

1. GDK,HTGD Self-branded famous manufacture around the world

2. Self developed and owned software, Company industry experience

3. 2000 sets production capability per year

4. CE,ISO,TUV certified company

5. We have many years of SMT sales, installation and after-sales service experience.

6. We have exported the whole line of SMT equipment in North America,South America, Europe, Southeast Asia, Middle East and other countries. Many of them are new customers starting from scratch.

7. We assist customers to train professional technicians and provide technical support at any time.

8. We solve all SMT problems for our customers.

Other Products Support:

Packing: Vaccum +Wooden Box.

-----------FAQ----------------------------------------------------

Q: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

Q:Are you a trade company or a manufacturer?

A: OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 35 days after receipt of payment.